Oil Condition Monitoring

The world's most advanced and flexible real-time oil quality condition monitoring sensor

Uses FSH™ technology to detect and measure any oil contamination or wear, with precise oil end of life

Can detect the slightest change in Oil condition, even +/-0.5% change, for any oil type, in any application

Oil Condition output direct to Displays and PLC systems, or IIOT enabled for condition Anytime Anywhere over the internet

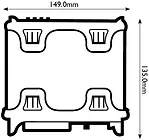

Oil Quality Sensor

FULL SPECTRUM HOLISTIC FSH™

Detects all wear and contamination: water, acid, fuel, viscosity, carbon, wear particles etc

REAL-TIME

Continuously analyses oil condition and reports oil condition every two seconds.

PARAMETERS MONITORED

Tan Delta Number TDN

Oil Temperature

ABSOLUTE ACCURACY

Oil quality change sensitivity detection of 0.01% (100ppm)

with accuracy margin of +/-0.5%.

OIL TYPE

All mineral, semi-synthetic or synthetic oils, including fuels (diesel & biodiesel)

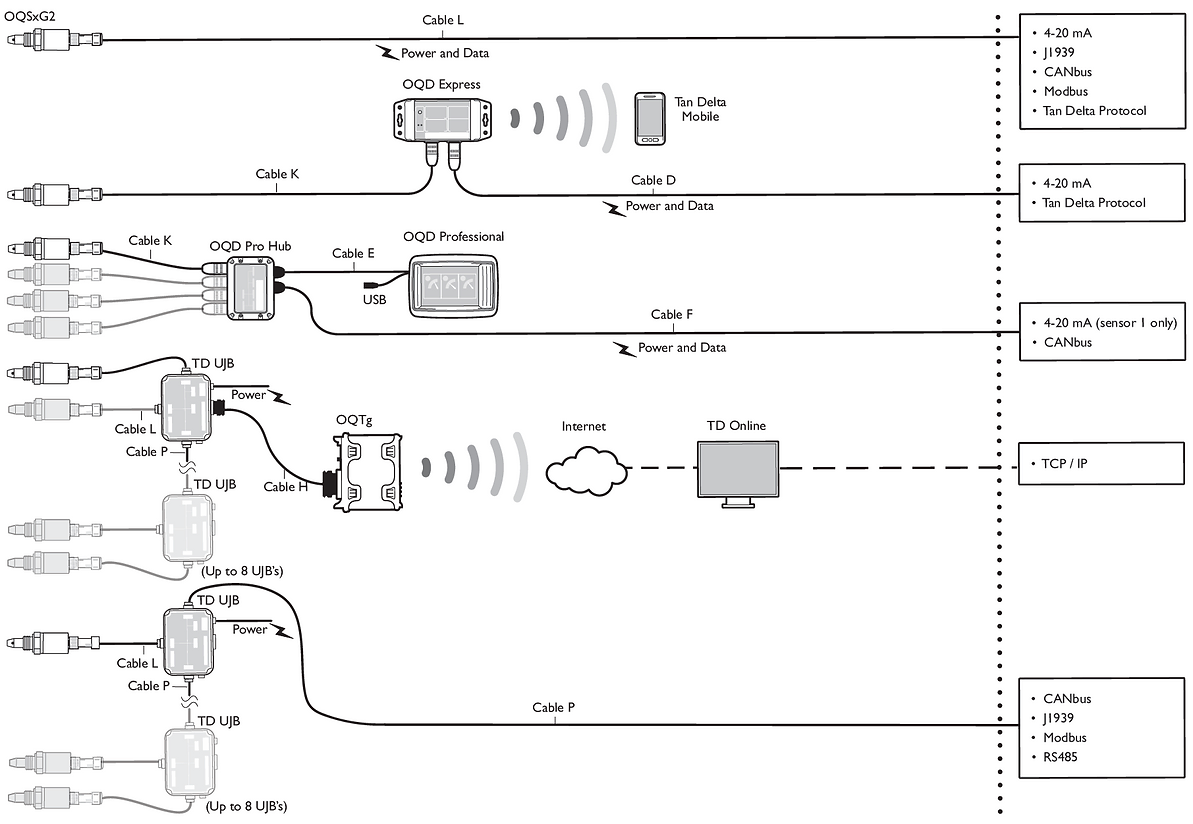

OUTPUTS

Digital: RS485, CANbus

Analog: 4-20mA

Protocols: Modbus, JI939

Sensor Output

Direct

PLC

Computer, CAD software

Display

Express

IIoT Gateway

Web Dashboard

Display EXPRESS

CONFIGURABLE OIL QUALITY ALERTS - Configurable traffic light alert system provides simple visual oil quality reference.

DATA LOGGER - Continuously logs up to 800,000 records of oil quality data which can be downloaded for analysis.

ESSENTIAL INFORMATION - Displays oil quality, temperature and rate of change in real time.

ROBUST & RELIABLE - Proven around the world for use in even the most extreme industrial and commercial applications, IP67

BLUETOOTH CONNECTIVITY - Stored data can be easily downloaded and sent wherever needed.

IIOT Gateway

SYSTEM INTEGRATION - can support 10 sensors simultaneously, with cables of varying lengths to ensure easy installation, integration and operation.

CONNECTS TO TD-ONLINE - a web interface that serves as a data hub and dashboard view of all monitored assets, with alerts. It is similar across desktop/tablet/smart phone views for ease of use.

SIMPLE TO DEPLOY - Allowing quick and simple installation on any piece of equipment whether brand new or being installed as part of a retrofit.

INDUSTRIAL QUALITY - IP67 rated, suitable for installation in any harsh industrial environment.

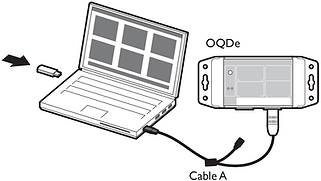

Mobile Oil Tester MOT

ALL YOU NEED - Everything you need to undertake instant oil analysis in one place.

PORTABLE - The MOT Kit is fully portable - ideal for the workshop and for field maintenance crews.

ROBUST & RUGGED - Housed in a rugged IP67 rated industrial quality case for carrying on site.

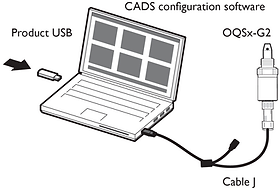

INSTANT RESULTS - Instant diagnosis of oil condition, with the ability to store and trend data. Install the supplied CADS software on your windows laptop/PC, connect the Oil Quality Sensor via the configuration cable to your laptop, present sample for instant diagnosis of condition, trend and store oil condition in the CADS software.

FULLY CONFIGURABLE - Suitable for use in any commercial or industrial environment, the MOT Kit allows accurate testing of any oil or fuel oil.

CADS Application

Configuration and Data Software CADS

FLEXIBLE CONFIGURATION - Enables the simple and easy configuration of all products to suit any applications with any oil type.

DATA ANALYSIS - Trend analysis allows you to maximise the benefits of your real-time oil monitoring data.

OIL DATABASE - Comprehensive database of oil configuration profiles for performance optimisation

AUTOMATIC UPDATES - Database & configuration tool updates done automatically via the internet.

WINDOWS COMPATIBLE - Fully compatible with all the supported versions of Windows from Windows 7 up to Windows 10.